Maintenance of wind turbine blades with drones

Nowadays, renewable energy has taken a strong position throughout the world and its share is already close to 30% of total energy production. One of the main directions in this area is wind energy, as the most accessible and independent of the season and time of day. By June 2023, the total capacity of wind turbines reached 1 TW. And, despite the fact that it took 40 years to achieve this level, reaching a power of 2 TW will happen much faster. According to experts, this will take only 7 years.

The image is designed by Freepik

The leading positions in terms of installed capacity today are occupied by countries such as China, USA, Germany, India, Spain, etc.

Problems of wind energy generation

Not everything is as smooth with wind turbines as we would like it to be. There are a number of problems that, to one degree or another, affect the efficiency of installations. Here is just a short list of the most well-known factors:

- Icing - can increase the mass of the blades and reduce the efficiency of the wind generator.

- Defects in the surface of the blades - over time, can lead to breakage of the blades and, as a result, failure of the installation and expensive repairs.

- Dust, paint wear and insects - reduce blade lift and efficiency by approximately 1.2% per year.

- Downtime - inspection using traditional methods involving climbers or lifting equipment requires a lot of effort, time and money.

Maintenance automation

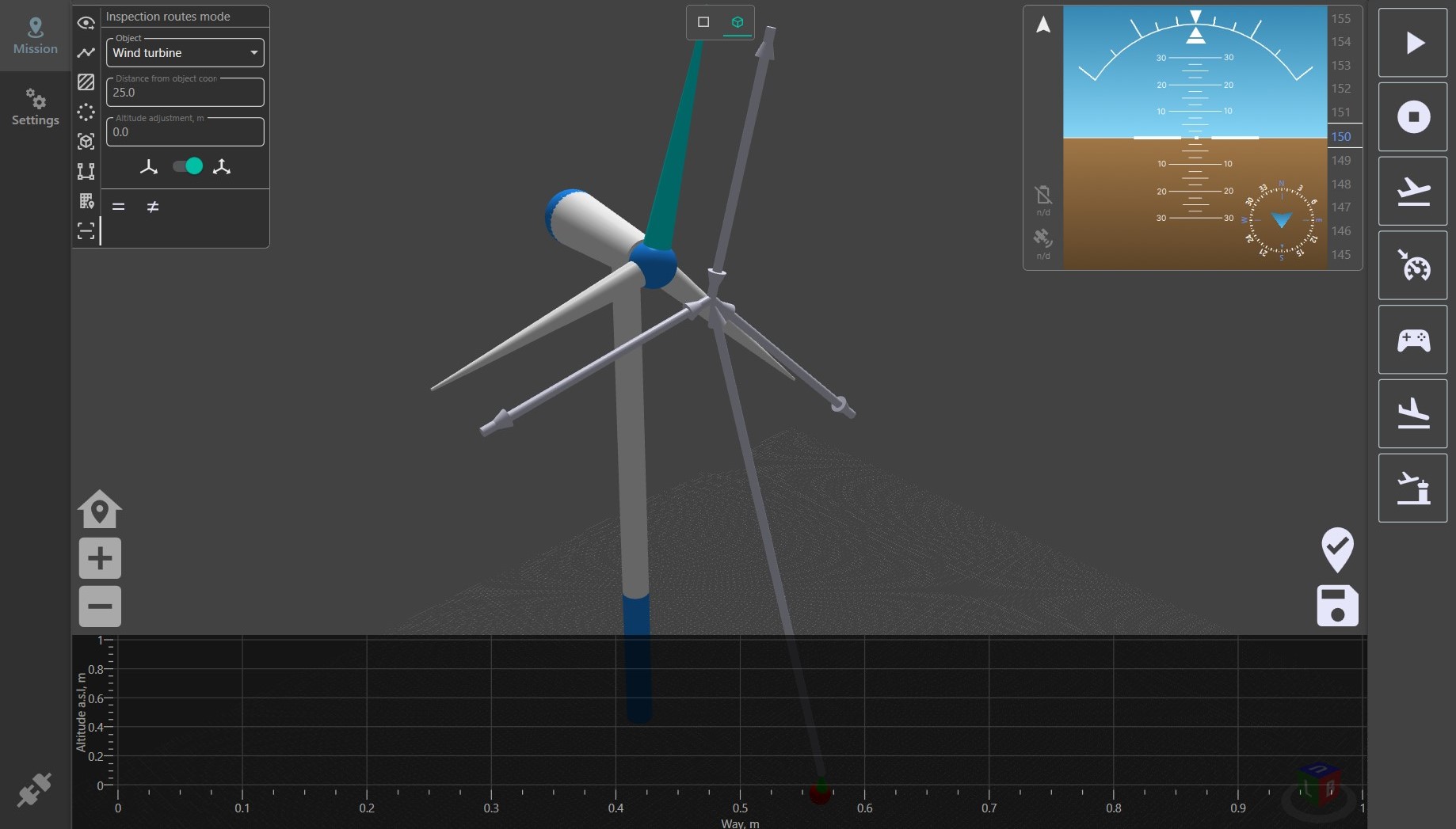

One of the most notable features of the LOGOS ground station is the ability to create routes for blade maintenance.

There is no need to set the wind turbine in a strictly defined direction, and the blades at a strictly defined angle. It is enough to determine the azimuth of the nacelle, the current angle of one of the blades and enter these parameters into the program: the route will be built with mathematical accuracy at the specified distance. If necessary, you can set the altitude adjustment so that the drone will fly a little higher or a little lower than the blade.

To do this, you just need to connect the "windmill" to the route, specifying the following parameters:

- Wind turbine geolocation

- Hub height

- Number of blades

- Rotor diameter

- Rotor angle

- Nacelle heading

Then, using inspection mode, allow the application to automatically build a route along the blades.

Also, it is worth noting that when using a UAV carrying a forward-facing sprayer on board, a route can be built to apply anti-icing or washing liquids.

Video demonstration of route for wind turbine maintenance

Details of creating a route for flying parallel to the blades are given here.

And for a more detailed understanding of working with GCS, it is recommended to study all the documentation.

Contact information

For any questions concerning our products and services you can reach out us by using the following contact information:

- Company: AEROLOGOS LLC

- Address: 220018, Republic of Belarus, Minsk, Maksima Gorezkogo 14, premice 503, room 4-63

- Email: contact@aerologos.by

- Phone: +375 (33) 662-05-81

- Website: https://aerologos.by

- Contact form

Interested?